Selection of metal halide lamps should be noted that different products , there are two categories: one used to call the American metal halide ballasts , sodium scandium American Standard ie , China has introduced 10 production lines , mainly such products ; Second Continental Gold halogen lamps , sodium thallium , indium Philips Osram lamps and metal halide lamps . Two types are available, their own characteristics, but must pay attention to their different starting performance , supporting different electrical accessories ;

According metal halide working substance named . Sodium scandium metal halide which is the working substance is a halide of scandium and sodium ; sodium thallium and indium in the metal halide lamp is the working substance is a halide of sodium , thallium, indium and other metals . This is the typical metal halide in the two series . Scandium sodium lamp series is now widely used in our country , but also the so-called American Standard series of lights. Sodium thallium , indium series of lights is widely used in Europe , the so-called European standard lamps.

1,4000-4500K Color Temperature

2 , CRI , Ra65-70

3 , high luminous efficiency , long life and reliable performance

5, for flood lighting, outdoor billboards , stadium lighting, etc.

American Standard Metal Halide lamps:

1 , requires the use of supporting CWA ballast , need not trigger a strong , anti- voltage fluctuation capability

2 , long life , up to 20,000 hours

3 , high luminous efficiency , and no burning position limit

4 , suitable for outdoor floodlight , billboards, industrial lighting , stadiums , golf courses , etc.

The so-called American standard metal halide lamp is by the American National Standards ANSIC78 series require the production of metal halide bulbs such as domestic JMS × × × KN series , is currently the most widely used metal halide light bulbs, the so-called European standard metal halide , mainly referring to EC by national standards ( according to EC national grid voltage 230V features ) produces metal halide bulbs, these lamps far as we know there is no complete production line introduction , but manufacturers have imported lamps liner assembly , as currently marketed HPI, HQI-E, HQI-T series. Two standard metal halide bulb from the light parameters and lifetime difference is not large , but the supporting electrical requirements are different ,

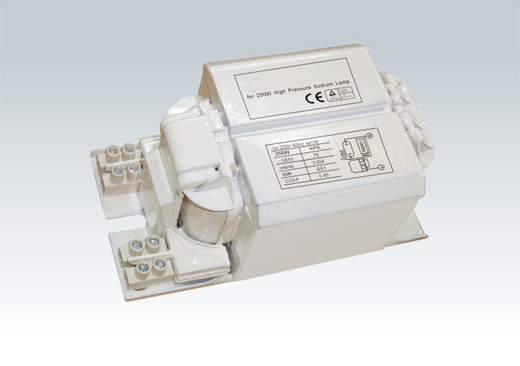

Metal halide lamp ballasts and supporting

American standard metal halide lamps and metal halide ballasts different European standard , European standard metal halide or mercury lines available sodium line , you can increase the inductance ballast trigger ; while the American standard metal halide should configure dedicated the SWA ballast, ahead of the summit that the formula ( magnetic flux leakage boost ) ballast, otherwise it will cause difficulty in starting , reduced luminous efficiency, color temperature instability, reduced lamp life .

As long as the European standard metal halide or

high pressure sodium lamp ballasts coupled with mercury ballast and trigger additional compensation capacitor can work reliably in our 220V 50Hz power line , lighting circuit shown in Figure 1 . European standard pulse start metal halide lamp , depending on the peak voltage can be divided into two start pulse amplitude of 0.6KV-1.5KV as HPI lamps, another 4.0KV-5.0KV as HQI-T metal halide lamp. American Standard Metal Halide Metal Halide not use the European standard electrical configuration because the minimum start- rms voltage (≤ 240V) lamp circuit in Figure 1 can not be obtained to meet the U.S. standard ANSI C78 Electric in light of the requirements listed in Table 1 ( matching appliances must be provided to the lamp brackets in Table 1 RMS voltage and form factor , reliable light to start ) , so the United States must be the subject of metal halide bulb lighting circuit configuration in Figure 2 ( LC peak ahead of ballast type magnetic flux leakage boost ballast output RMS voltage and light form factor to meet the requirements ) , in order to ensure the bulbs work .

View of an additional

Ballast itself should not be of European standard, American standard , ballast design and selection depends on the characteristics of the lamp service parameters and supply voltage. The so-called " American Standard ", " European standard " is different in the ballast , mainly in Europe and the United States the power supply voltage is different. Voltage is 120V in the United States while in Europe is 220V , China's supply voltage and substantially the same or close to Europe , so we are using the European standard lamps and ballasts . American Standard ballast using a boost ballast , which is equipped with capacitive leakage transformer , while the European standard is mainly used in magnetic ballast matched trigger. For the purposes of small power no distinction between European standard and American targets . Even with " American Standard " light , due to power relations , may also have so-called European standard ballast.

View of two additional

American Standard ballast leakage magnetic ballast for general use , but mostly with European standard electronic ballasts for metal halide MH liner in terms of the American general auxiliary electrode , because the American standard voltage is only 110V, current is relatively small unplayable plus auxiliary electrode wear it to help start a strong magnetic flux leakage itself must boost device , so some lights do not need to use a trigger. European standard lamps are also available in the U.S. standard line , but because the line itself and ballast than with issues affecting large luminous flux and life cut short , in addition to the American standard lamps can also be used in the European circuit . Specifically the sodium slightly different in size only .